On the occasion of the fortieth anniversary, Xiexu Machinery Co., Ltd. joined hands with Suzhou Pumak Energy Conservation Technology Co., Ltd. to give a heavy gift, upgrade the process of the original cardboard line, and comprehensively introduce a new generation of high-speed energy-saving tile line to the market. At present, this tile line has been successfully operated in Xiexu Machinery Client. The average speed of producing five-storey high-gram heavy cardboard is up to 200 meters per minute. Moreover, the tile line can also produce functional paperboard, such as film-coated paperboard and water-resistant paperboard of fruit cold chain, which can not be produced by ordinary tile line due to high temperature, thus creating a new profit model for paperboard mills.

Source: Author of Huayin Carton: Xiaozheng, Huayin

Xiexu joined hands with Pumak to launch a high-speed energy-saving tile line with an average speed of 200 m/min for five-ply panels

It is reported that the maximum speed of this high-speed energy-saving cardboard line can reach more than 300 meters per minute, the production speed of five-storey heavy cardboard can be stabilized at 200 meters per minute, and the production speed of seven-storey cardboard can reach 180 meters per minute. At present, this tile line has been successfully operated in Xiexu Machinery Client, for example, Huiying Paper Industry in Guangxi has two 2.5 meters wide wires in use. Li Yanbin, general manager of Huiying Paper Industry, commented, "The future development trend of the industry must be intellectualization, downsizing and efficiency enhancement. Xiexu's products meet the development needs of our company and are a powerful force for us to open up the market."

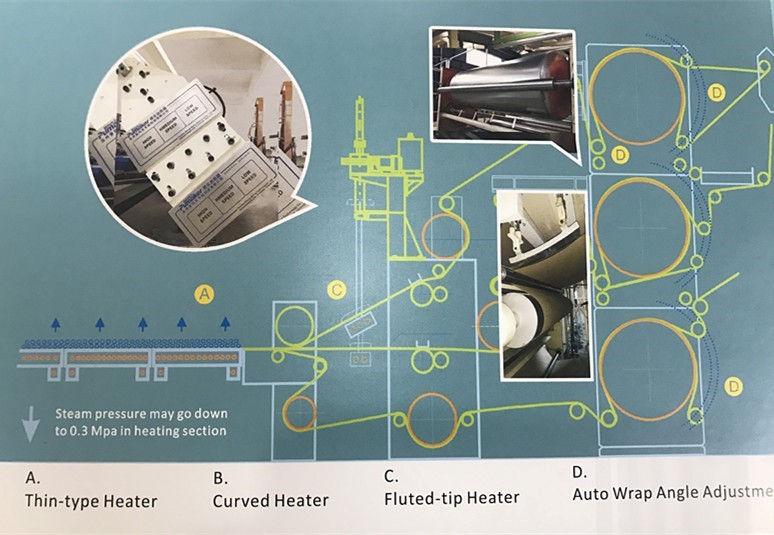

Partner Pumak is a technological innovative enterprise focusing on energy saving of tile line. It has more than 20 years of process optimization experience in this field. It is good at integrated heating process solutions such as runner hot plate, arc plate and corrugated heater. After the cooperation between the two sides, the technical team proceeded from the production process of cardboard, carried out empirical research on each heating link in the production process, and finally put into the R&D and design of high-speed energy-saving tile line.

Asked about the reasons for the cooperation with Pumak, Mr. Lu of Xiexu Machinery said: "Today, the profit of carton industry is diluted, and the new concept of integration of equipment and technology is changing the industry's expectations for cardboard equipment suppliers. The strategic cooperation between Xiexu Machinery and Pumaker is the combination of equipment advantages and technology. We will devote ourselves to providing integrated service of "equipment + technology" for our customers, helping them to build core competitiveness of high efficiency, energy saving and cost reduction, and creating more operating profits!”

![]()

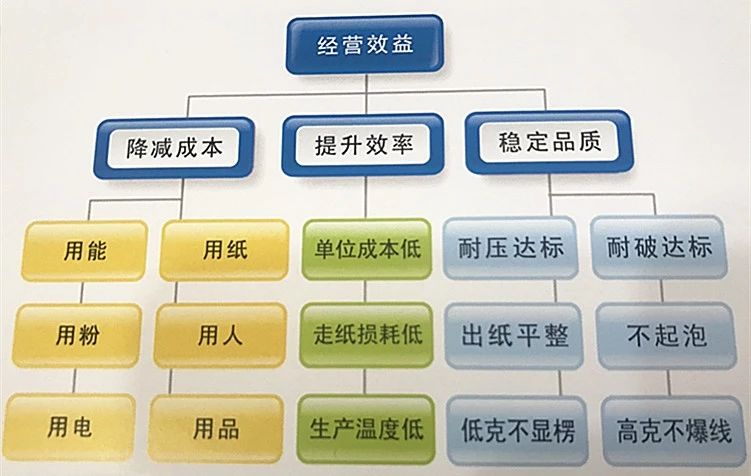

Subvert the traditional concept of cost and create a new profit model for cardboard mills

Xiexu high-speed energy-saving cardboard line has overturned the traditional cost concept. It can not only achieve high-speed production, but also reduce the use of steam, paste and starch. The powder consumption per ton of paper is as low as 15 kg, the steam pressure of the whole line is 5 kg, and the temperature of hot plate is reduced to 120 C. Moreover, the quality of the produced cardboard is better than that of the peers, but the processing cost is much lower than that of the peers.

In addition, with Pumak patented corrugated heater and thin hot board, the operation speed has been greatly increased, the surface temperature of hot board has been lowered, so that tile line has the special functions of producing waterproof, film-covering, high-gloss and wear-resistant pre-printing board, such as Film-covering board, high-gloss and wear-resistant pre-printing board, water-resistant paper board of fruit cold chain... With the help of corrugated heater, cardboard mills can successfully seize the new blue sea market and create innovative profit models.

|

1、Efficient production: Xiexu high-speed energy-saving cardboard line can enable customers to achieve an average speed of 180-200 meters per minute for five and seven layers of cardboard. The unit cost of paperboard processing is low, the paper loss is low, and the production temperature is low. 2. Cost reduction: a new type of corrugated heater can greatly shorten the gelatinization time of corrugated starch; a thin runner hot plate can accelerate the bonding and solidification process of cardboard; an arc preheater can compensate for the linear elasticity of cardboard; a double-sided machine can quickly adjust and control the temperature to meet the requirements of various materials; reduce the surface temperature of hot board to avoid deterioration of paper physical properties; precisely control the bonding of cardboard to reduce failu

3. Energy-saving and cooling: It can operate in low temperature and low pressure environment, save steam energy, ensure the original physical properties of cardboard, make the cardboard smooth, burst and pressure-resistant, non-foaming, low grams of non-corrugating, high grams of non-explosive wire, etc., to avoid the bad return of cardboard caused by high temperature.

4. Entering the Blue Sea market: Cooling down the production of cardboard can help cardboard mills open up new markets for functional cardboard, seize new opportunities and earn high processing profits. |

It is gratifying that Xiexu will also provide a full range of services to customers, including new machine commissioning, plant design planning, energy-saving heating devices, equipment selection services, equipment renovation consulting, whole line novice training, energy-saving technical guidance, tile line production diagnosis and so on.

![]()

For 40 years, we have devoted ourselves to the construction of equipment quality. Xiexuwa Line enjoys a good reputation in the industry with its large sales volume and good reputation.

Since its establishment in 1980, Xiexu Machinery has been engaged in the R&D and manufacture of corrugated board production equipment with advanced technology, professional knowledge and computerized management. In order to fully grasp the efficiency and quality of production, related enterprises have been set up successively to carry out the processing and manufacturing of important components, and complete the planning, design, manufacture and installation of a complete set of corrugated board machines with standardized and consistent operations.

Over the years, Xiexu equipment has been sold all over the world, providing more than 1000 sets of complete plant equipment, among which the occupancy rate in Asia is the highest in the industry. The Group established Dongguan Xiexu Machinery Co., Ltd. in 1997, Kunshan Xiexu Machinery Co., Ltd. in 2006, Jiangxi Xiexu Machinery Co., Ltd. in 2008 and Chongqing Xiexu Machinery Co., Ltd. in 2012. Since then, Xiexu has appeared in the industry in the form of "five in one" groups of Xiexu in Taiwan, Dongguan, Jiangxi, Kunshan and Chongqing, providing customers with 24-hour fast, effective and comprehensive services with a more perfect organizational structure.

As a subsidiary company of Xiexu Machinery, Jiangxi Xiexu Machinery Co., Ltd. was established in 2008. It is the whole production base of Xiexu Machinery in mainland China. In the course of more than ten years'development, relying on the technical support of Taiwan Headquarters, Jiangxi Xiexu has continuously developed corrugated machinery technology, and has sold up to hundreds of high-speed corrugated board production lines of various specifications, winning branches of Shengyuan Group, International Paper Industry, Dongjing Holdings, Yongfengyu Paper Industry, Jifeng Group, Hexing Packing Industry, Jinshan Paper Industry, Longxiang Packing Industry and other well-known packaging enterprises at home and abroad. Trust and trust. For example, Xiexu's old customer Shengyuan Group has ordered more than 20 high-speed production lines from Xiexu Machinery since 2013, most of which are 2.5 meters wide and 2.8 meters wide.

△ Guests visited the 2.5m corrugated cardboard line of Xiexu, Hexing, Hubei Province. The highest speed of the day was 256m/min.

△In 2015, Longxiang packaging in Zhejiang Province was equipped with Xiexu Machinery's 2.5-meter seven-layer high-speed corrugated cardboard production line, reaching an average of 170 m/min per month, with an annual output value of 400 million yuan.

In addition, as a major gift for the 40th anniversary, Xiexu is also building a 5.0 edition of the whole plant logistics planning synchronously to help carton enterprises break away from the crowd tactics and truly realize the unmanned whole plant. According to leaks, at present, there are cardboard factory customers signed cooperation agreements. More details, please look forward to!

|

Xie Xu machinery Xiexu high-speed energy-saving cardboard line is committed to helping the carton industry to build a core competitiveness of high speed and low energy consumption, to enhance and create operating profits for customers, and to escort the strategic development of enterprises! Welcome new and old customers for further consultation! Miss Lu 0512-57868591!

Taiwan Xiexu Group HSIEH HSU MACHINERY Address: 141 Luzhu Street, Luzhu Village, Taoyuan County, Taiwan Province Tel: +88633221314 Fax: +88633226206 Website: www.hsiehhsu.com.tw

Jiangxi Xiexu Machinery Address: 23 Gongxin Avenue, Yifeng County Industrial Park, Jiangxi Province Tel: 0795-2290106 Fax: 0795-990109 << |