[Abstract] On March 22, the second day of the China-India Asia Corrugated Exhibition, China-India Editorial visited some exhibitors and learned about the harvest of the exhibition. Today China-India Editorial also interviewed Xiexiu, Fumai, Chenguang, Derry and Chenxin. More interviews with exhibitors will be reported in the follow-up. Please look forward to them!

This is a 350 meter paper machine, mainly for the high-end market. Generally speaking, high-speed machine will be matched with such a product, we are now mainly matched with Fosber, BHS, Jingshan, Xiangyi high-speed line, some high-speed production line to match the paper machine. This paper machine is a more classic Ma Gui design. The head part of the paper is modeled after the design of the American Ma Gui, and the control part is developed by ourselves, which can also cope with various situations.

It has three cushioning rolls and two-section drive, which is different from most of the paper machines on the market. It can be said that Fumai is an early enterprise in the paper machine industry, and has maintained relatively high sales in recent years. Our direction in these years I think is that customers will pay more and more attention to it. The speed and stability of the paper machine, we also see many, including imported paper machine can not achieve stability at high speed, we are also working in this area, we may develop a higher speed, more stable paper machine.

If we are in China, we have about 30-40% market share, anyway, we sell about 400-500 paper machines a year. That's how much we can produce. The biggest problem now is that we have a problem of delivery. In fact, our capacity is already saturated, so we will be in the future. A more factory in Henan can expand our capacity.

We do better overseas, we have our products in most of the developed packaging areas around the world, we have our products in the Americas (South America and North America), including Mexico, Central America and North America, and then we have our products in Europe and even Germany. We do this comparison overseas. Earlier, we were very well-known in Southeast Asia. This morning the guests came in and just saw the word "Fumai" and they knew it was our paper machine. I think it means that in Southeast Asia as well as in other countries all over the world, the development is good. The emphasis is that we are preparing to develop the Indian market these years. We also spend a lot of energy in India, and we will find some good partners to develop the Indian market.

General rule

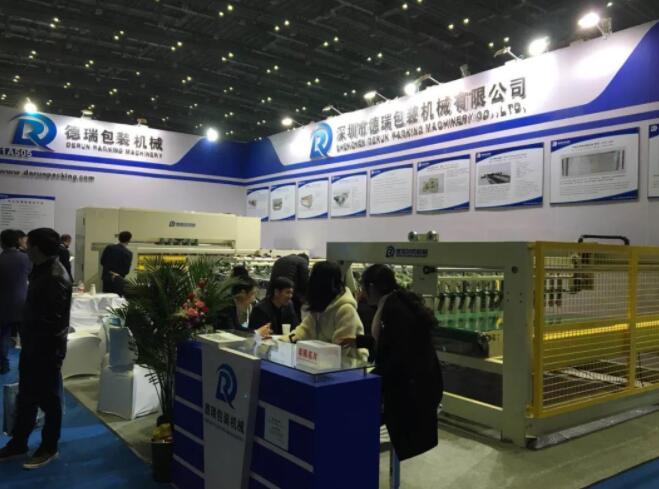

Derry Packaging Machinery Co., Ltd.

Our equipment is now one of the most advanced configuration in our industry, another is our Derry company is a young company, but also a high-tech company, our equipment, including mechanical research and development of the entire electronic control are our own research and development, this is compared with our counterparts in the market. We have the advantage of cost and R&D, so our company has more than 40 customers in our country through two years'development, and our customers have a good reputation for our company and a good evaluation of us.

Our customers are mainly from Zhejiang and Shanghai, then Hubei and Hunan, mainly from all the provinces in the country, except the northwest, which basically have customers, and we have a lot of big companies cooperating. For example, Hexing Group, at least eight subsidiaries have equipment with us. Cooperation.

Overseas there is a Philippine market, with agents to do with us. We can sell more than 10 sets of equipment in a year's Fibbin market. After-sales service is basically a timely solution to customers inside the phone, we usually send people to the scene within 12 hours to do maintenance for customers. At present, like foreign customers, we are like foreign customers. We all have a very good after-sale for them, foreign customers do not have to buy our equipment can not be guaranteed. Another, our equipment, I think I design is more humane, the operation of all aspects is relatively simple.

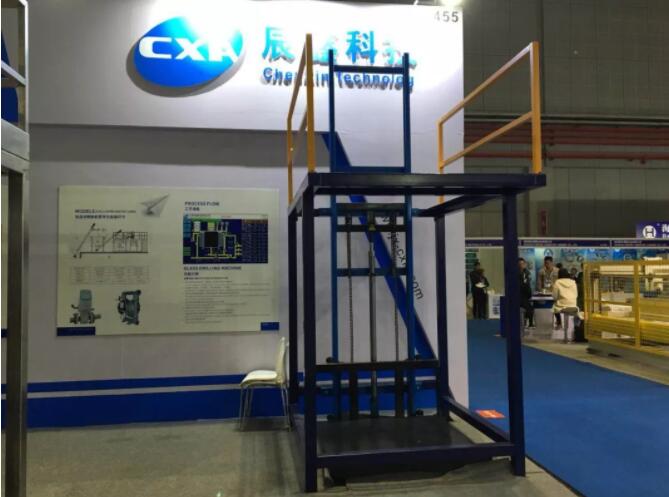

Jiangxi Chenxin Technology Co., Ltd. showed us the CXA-3000Y/H automatic glue making system. Mr. Lin Bo, general manager of Chenxin, introduced the equipment in detail in the interview.

Lin general:The whole glue system is made of stainless steel. Then, we use one spare, that is, two sets of automatic viscosity measurement system, if one is broken, the other can be used immediately. Prevent customers from viscosity problems, resulting in glue instability. This is unique in the industry. Yes! For the cost aspect, one spare must be a little bit more expensive, but the benefit will be greater.

We also brought a set of automatic lifting system, that is, material lifting system, mainly to save labor costs. This system for glue, borax, caustic soda, including additives and so on, like many large factories, before the use of large quantities, were carried to the machine manually, so the first person is more tired, the second person compared. Dangerous, because people go up stairs and get hurt in case they fall down. We use this lifting system, which is towed directly to the top with a trailer, lifted directly with hydraulic pressure, and held on to it.

Mr. Lin Bo, general manager of delta Chen Xin